Preface

Studies have shown a consequential association between human exposure to particulate matter (PM) and health risks. It has been established that fine dust can be a serious health hazard, contributing to or even causing respiratory and cardiovascular diseases.

Until recently, most standards for heating, ventilation, and air-conditioning (HVAC) have been primarily concerned with the design and performance of HVAC systems. However, attention also needs to be paid to the increasingly important fields of air filtrations where issues of particulate matter and associated risk are found.

Overview – Why air filtration is required?

Clean air is the basic requirement of human health and well-being. However, air pollution continues to pose a significant threat to health worldwide. According to a World Health Organization (WHO) assessment of the burden of disease due to air pollution, more than 2 million premature deaths each year can be attributed to the effects of urban outdoor air pollution and indoor air pollution (caused by the burning of solid fuels).

Indoor Air Quality (IAQ) is an area that focuses on providing a comfortable and healthy indoor environment that is important to the well-being of people since we spend 90% of our time in the indoor spaces and the issue of IAQ is a key aspect of public health, especially since this affects the entire population, particularly the most sensitive and vulnerable.

Different classes of particulate matter can be defined according to the particle size range. The most important ones are PM10, PM2.5, and PM1. The World Health Organization (WHO) defines PM10 as a particulate matter which passes through a size-selective inlet with a 50 % efficiency cut-off at 10 μm aerodynamic diameter. PM2.5 and PM1 are similarly defined.

Refrigeration and Air Conditioning Sectional Committee, MED 03 under the Mechanical Engineering Department of BIS is working in this area. The sectional committee took cognizance of the issue and has published a series of standard on the subject.

IS 17570 / ISO 16890 (4 parts) refers to particulate air filter elements for general ventilation having an ePM1 efficiency less than or equal to 99 % when tested according to the procedures defined within IS 17570 / ISO 16890 series as follows:

i) IS 17570 (Part 1) / ISO 16890-1, Air filter for general ventilation — Part 1: Technical specifications, requirements and classification system based upon particulate matter efficiency (ePM)

ii) IS 17570 (Part 2), Air filter for general ventilation — Part 2: Measurement of fractional efficiency and air flow resistance (ISO 16890-2 : 2016, MOD)

iii) IS 17570 (Part 3) / ISO 16890-3, Air filter for general ventilation — Part 3: Determination of the gravimetric efficiency and the air flow resistance versus the mass of test dust captured

iv) IS 17570 (Part 4) / ISO 16890-4, Air filter for general ventilation — Part 4: Conditioning method to determine the minimum fractional test efficiency

IS 17570/ ISO 16890 series supersedes ‘IS 7613: 1975 Method of testing panel type air filters for air — Conditioning and ventilation purposes’.

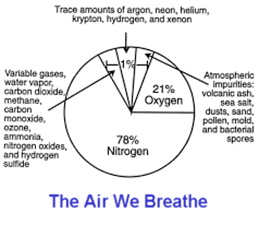

Particulate matter in the context of the IS 17570 / ISO 16890 series describes a size fraction of the natural aerosol (liquid and solid particles) suspended in ambient air.

In other words, poor air quality results from particulate matter (PM) in the air. PM comprises a complex mixture of solid and liquid particles and organic and inorganic substances suspended in the air. The major components of PM are sulphate, nitrates, ammonia, sodium chloride, black carbon, mineral dust, and water. PM sources are man-made or natural. Air pollution therefore varies from place to place.

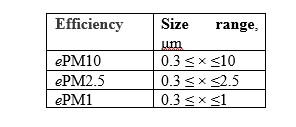

The symbol ePMx describes the efficiency of an air cleaning device to particles with an optical diameter between 0.3 μm and x μm. The following particle size ranges are used in the IS 17570 / ISO 16890 series for the listed efficiency values.

Optical particle diameter size ranges for the definition of the efficiencies, ePMx

Air filters for general ventilation are widely used in heating, ventilation, and air-conditioning applications of buildings. In this application, air filters significantly influence the IAQ and, hence, the health of people, by reducing the concentration of particulate matter. To enable design engineers and maintenance personnel to choose the correct filter types, there is an interest from international trade and manufacturing for a well-defined, common method of testing and classifying air filters according to their particle efficiencies, especially concerning the removal of particulate matter.

Current regional standards are applying different testing and classification methods, which do not allow any comparison with each other and thus hinder global trade with common products. Additionally, the current industry standards have known limitations by generating results that often are far away from filter performance in service, i.e. overstating the particle removal efficiency of many products.

With the new IS 17570 / ISO 16890 series, a completely new approach for a classification system is adopted, which gives better and more meaningful results.

The IS 17570 / ISO 16890 series describes the equipment, materials, technical specifications, requirements, qualifications, and procedures to produce the laboratory performance data and efficiency classification based upon the measured fractional efficiency converted into a particulate matter efficiency (ePM) reporting system.

Air filter elements according to the IS 17570/ISO 16890 series are evaluated in the laboratory by their ability to remove aerosol particulate expressed as the efficiency values ePM1, ePM2.5, and ePM10.

The particulate removal efficiency of the filter element is measured as a function of the particle size in the range of 0.3 μm to 10 μm of the unloaded and unconditioned filter element as per the procedures defined in IS 17570 (Part 2). After the initial particulate removal efficiency testing, the air filter element is conditioned according to the procedures defined in IS 17570 (Part 4)/ISO 16890-4 and the particulate removal efficiency is repeated on the conditioned filter element.

This is done to provide information about the intensity of any electrostatic removal mechanism which may or may not be present with the filter element for the test. The average efficiency of the filter is determined by calculating the mean between the initial efficiency and the conditioned efficiency for each size range. The average efficiency is used to calculate the ePMx efficiencies by weighting these values to the standardized and normalized particle size distribution of the related ambient aerosol fraction.

When comparing filters tested in accordance with the IS 17570/ISO 16890 series, the fractional efficiency values shall always be compared among the same ePMx class (example, ePM1 of filter A with ePM1 of filter B). The test dust capacity and the initial arrestance of a filter element are determined as per the test procedures defined in IS 17570 (Part 3)/ISO 16890-3.

Importance of Air Filtration

People spend an average of up to 90 % of their life indoors. Not only at home, but in various places such as offices, schools, restaurants, shopping malls, cinemas, etc. Having clean air indoors is crucial for the health of the population as a whole and in particularly vulnerable groups such as children, sick, or the elderly.

Air filtration technology is most widely used to remove particles from an air stream. Air filtration supplies the means to obtain the level of particulate cleanliness required by any definition of ‘air conditioning. It extends from the simple task of preventing lint and other debris from plugging heating/cooling coils to removing particles as small as 0.1 microns which could cause a short circuit on a microchip.

In addition to the reasons given above, air filters are used for a wide variety of purposes, some of which include1 :-

1National Air Filtration Association (NAFA), The Importance of Air Filtration

ePM1 – The New Focus to Protect Health

The understanding of the harmful health effects of exposure to air pollution has grown exponentially in recent years. Studies have shown that the sub-micron particles known as PM1 can cause serious illness.

There are, indeed, very effective ways to mitigate the impact of poor air quality within the buildings. The latest air purification technology controls the indoor environment, creating ‘safe havens’ where occupants can be confident that the air is free from the most dangerous particulate matter.

Transition to the New Standards

The aim of using air filters is to protect people’s health by maintaining a good hygiene level in the ventilation system and clean IAQ. It is commonly known that air pollution is unhealthy, but it is not so well known that the smallest particles are the most dangerous. The aspects could be different depending on the outdoor air quality and the indoor activities.

The industry was driven towards the filters classes viz. EU4, G4, MERV 8, etc due to the availability of multiple standards and lack of awareness. Mixing of filter classes with filter efficiencies came into the scenario and it became a challenge for the industry professional.

IS 17570:2021 / ISO 16890:2016 series has cleared the path ahead for the industry to use active standards and upgrade the technology.

By

Mr. Rajneesh Khosla, H(MED), Bureau of Indian Standards,

Ms. Khushbu Jyotsna Kindo, Sc. C, Bureau of Indian Standards,

Mr. Anil Chopra, Camfil India Private Limited &

Ms. Meena Kapoor, Camfil India Private Limited.